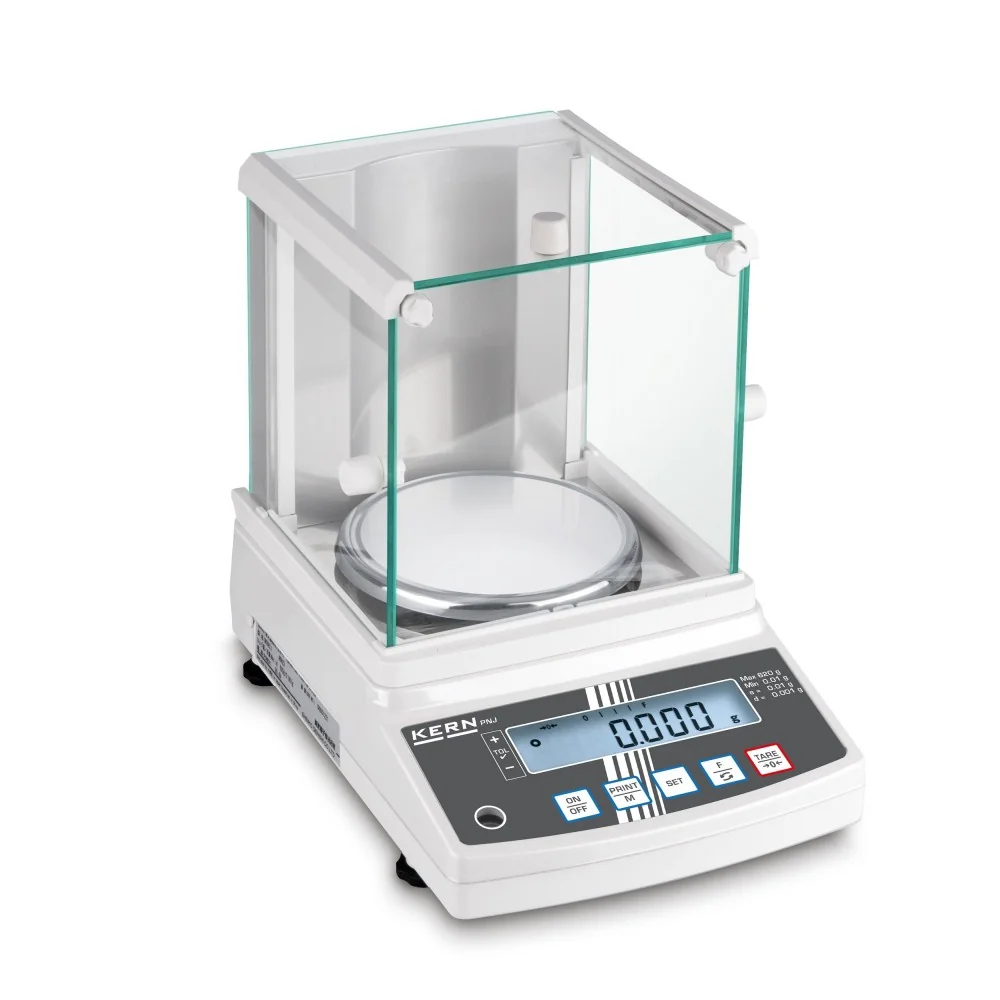

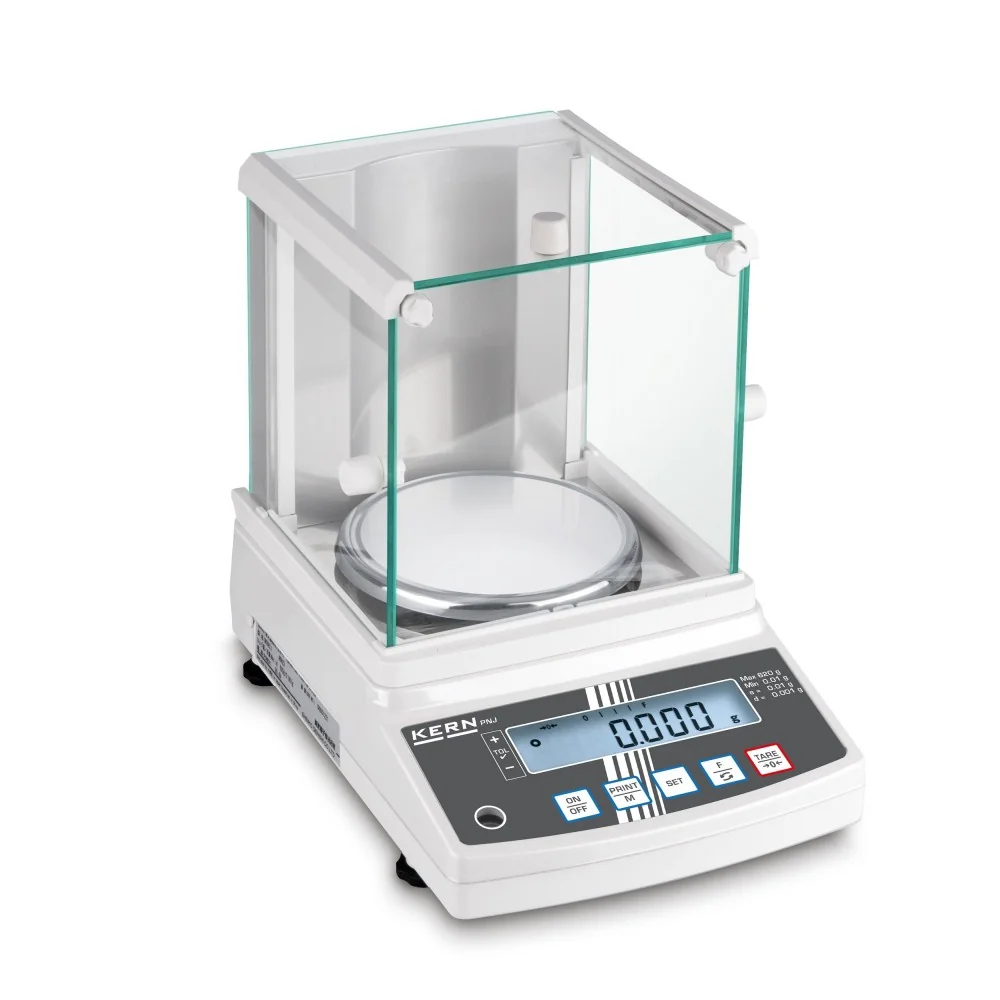

KERN PNS 600-3 Precision balance

PNS 600-3

with robust tuning fork weighing system

with robust tuning fork weighing system

FUTURES

OPTIONS

Shipping costs are calculated according to the size, weight and delivery address of the package.

Put the desired items in the shopping cart, enter the delivery address and you can see the different shipping methods and shipping costs

We are committed to ensuring that your order reaches you promptly and safely. We offer various shipping options to suit different needs and timelines. Please review our options below to select the one that best fits your requirements.

1. Economy Shipping

2. Standard Shipping

3. Express Shipping

4. Pallet Shipping (Freight Forwarder)

5. Shipping with Your Own Customer Account